This month Alex taught three of us how to make silicone moulds, mix resin, and make our own dice!

Alex has been trying out casting techniques for dice for a while on his own, and shared his knowledge with us by organising a hands-on workshop where we could try it out.

The process went like:

Day 1 - making moulds

The moulding process started with making a silicone mould of an existing dice. We chose to use dice from our personal collections, but just as easily could have used a 3D printed blank. This mould needs somewhere to pour the resin eventually, so we attached “sprues” to our dice which – when taken out – would form the negative space of a funnel.

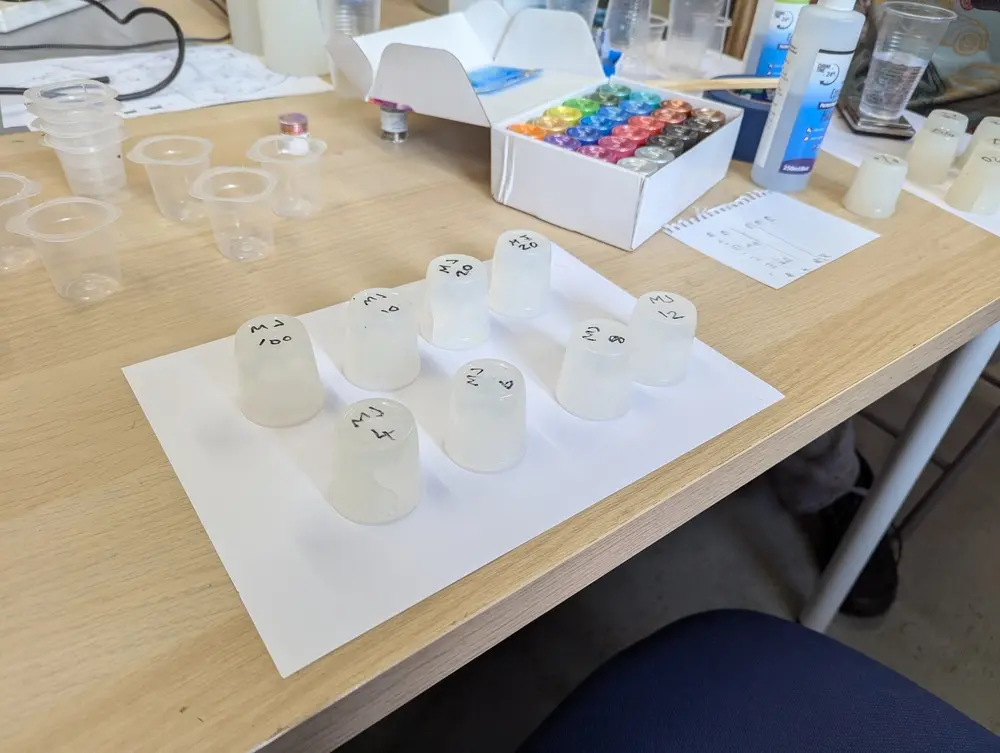

Then, we mixed together silicone by mixing equal-mass “Part A” and “Part B”. Once mixed, we each had 8 minutes to make all of our moulds.

At the end of our busy 8 minutes, we all placed our moulds in the pressure pot, which ensured that the silicone was as free of bubbles as possible while it cured.

Silicone should take a couple of hours to set, but the space wasn’t quite room temperature, extending the wait time. We decided to leave and come back in two days.

Day 2 - mixing resin

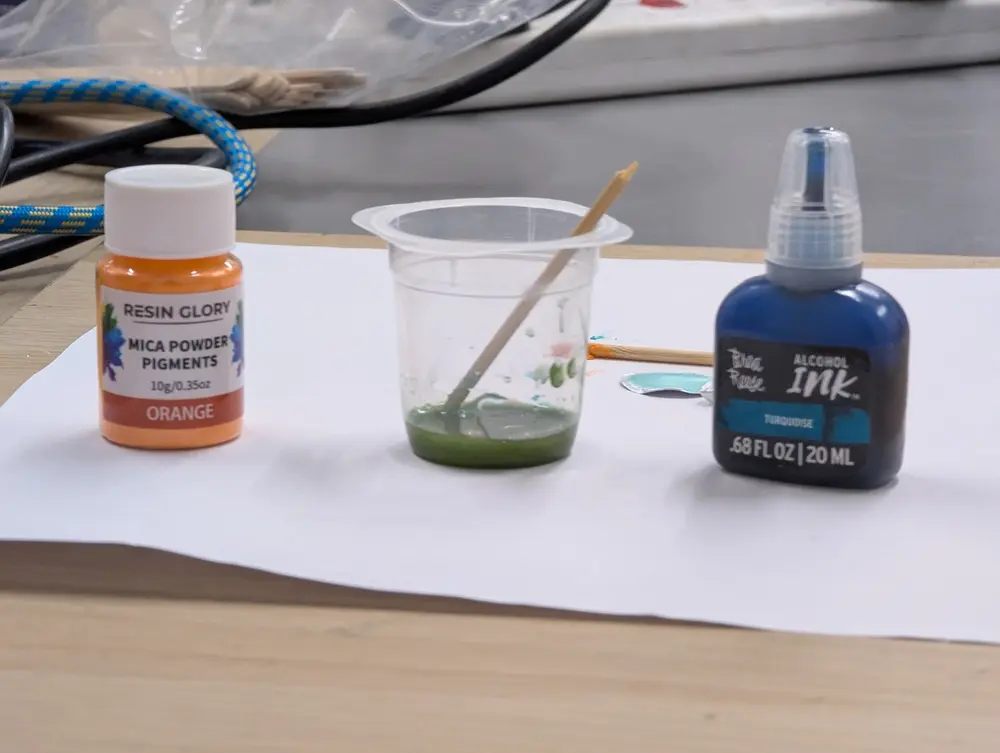

With our time waiting for silicone to cure, we played around with mixing resin, using alcohol inks and mica powder to create translucent mixes. We put these in the pressure chamber with the moulds to test the colours.

We took the silicone moulds out of the pressure pot, and used a scalpel to cut three jagged lines from the top down. This allowed us to pry out the blanks (dice) and be left with empty silicone moulds.

We each mixed our own resins, which thankfully gave us more time to work than the silicone (about 40 minutes).

For my dice I went for a blend of half “orange dye and blue mica powder” and half “blue dye and orange mica powder” (attempting a split-look). For the D1 that I cast I went for “pure purple”.

Then, we all together put our filled moulds into the pressure pot, this time for at least 2 days to allow the resin to cure. Again, the pressure pot to reduce bubbles.

Day 3 - finishing

We came back to our dice after about a week, giving the resin plenty of time to set.

We took the filled moulds out of the pressure pot, pryed apart the silicone, and got the resin objects out.

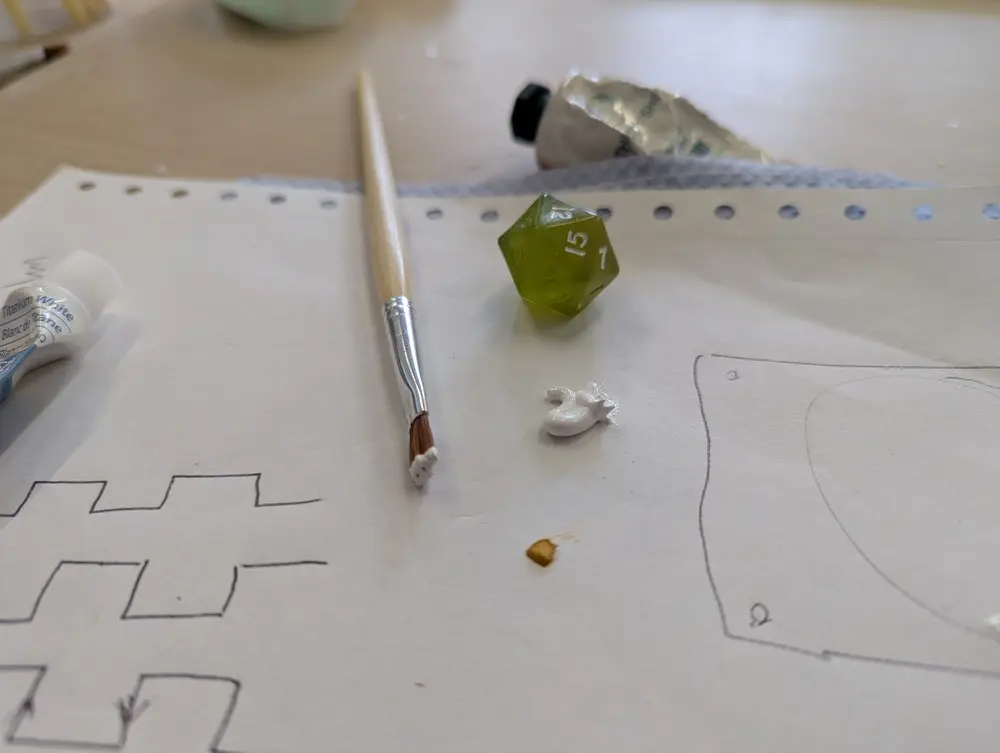

The silicone moulds (and thus the resin) picks up extraordinary levels of detail from the original item. It also picks up the sprue (pouring funnel), so we had to snap those off, then cut and sand down where it was attached.

Finally, we painted the numbers on. Since the numbers were recessed, the easiest way to do this was to paint the entire face sloppily, then wipe off the paint from the surface, which leaves paint in the recessed number.

I was very happy with the final dice.

Workshops at the space

This was one of the few workshops that have been happening recently around Sheffield Hackspace.

To find out what workshops are happening soon, you can check the wiki page or the events feed on Discord. Both of these require being a member of the Discord server. You can join the Discord server by coming down to an open evening :]