What have members of Sheffield Hackspace been up to this month?

Let’s find out!

- Nik - window decoration

- Nik - an LED device

- Alex - a trip to soft lab

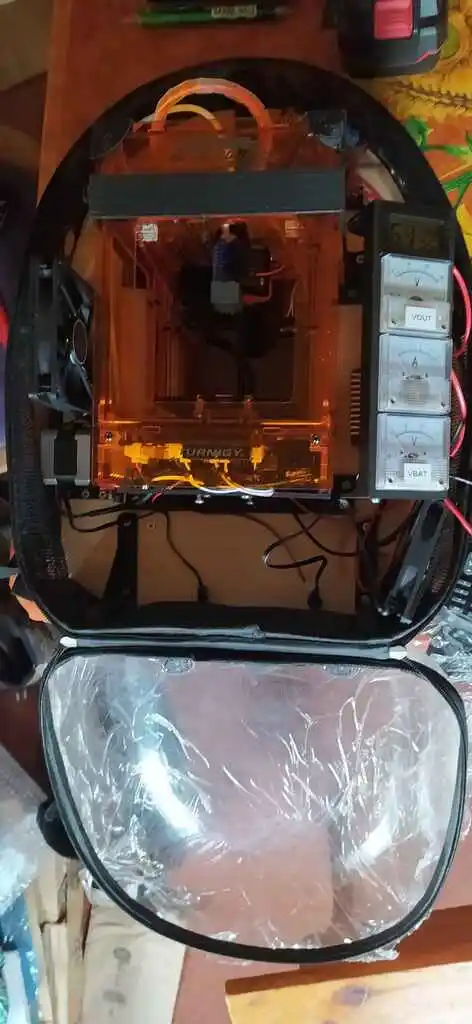

- James - 3D printer in a backpack

- Adam - organised electronics

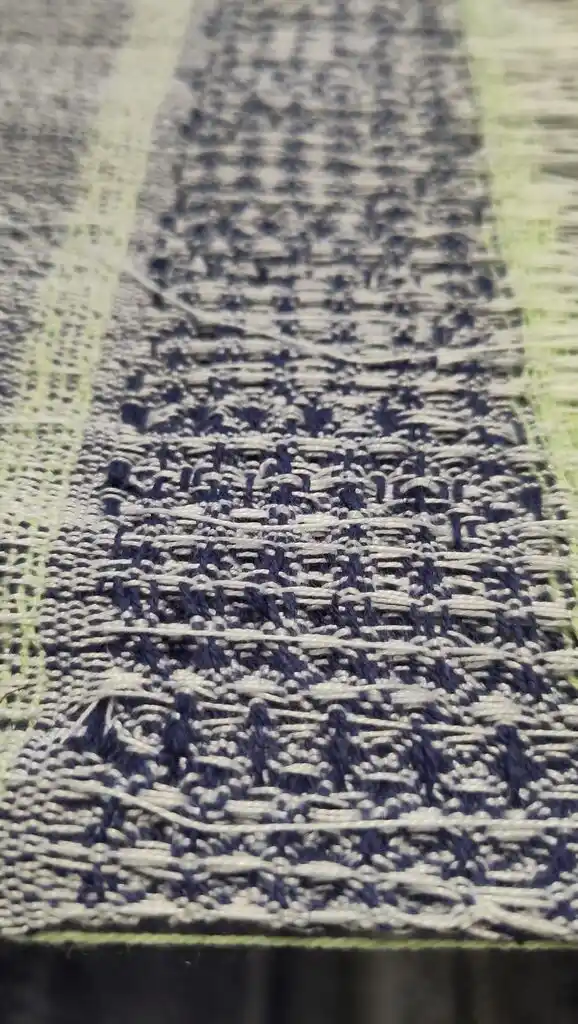

- Tom - darning repairs

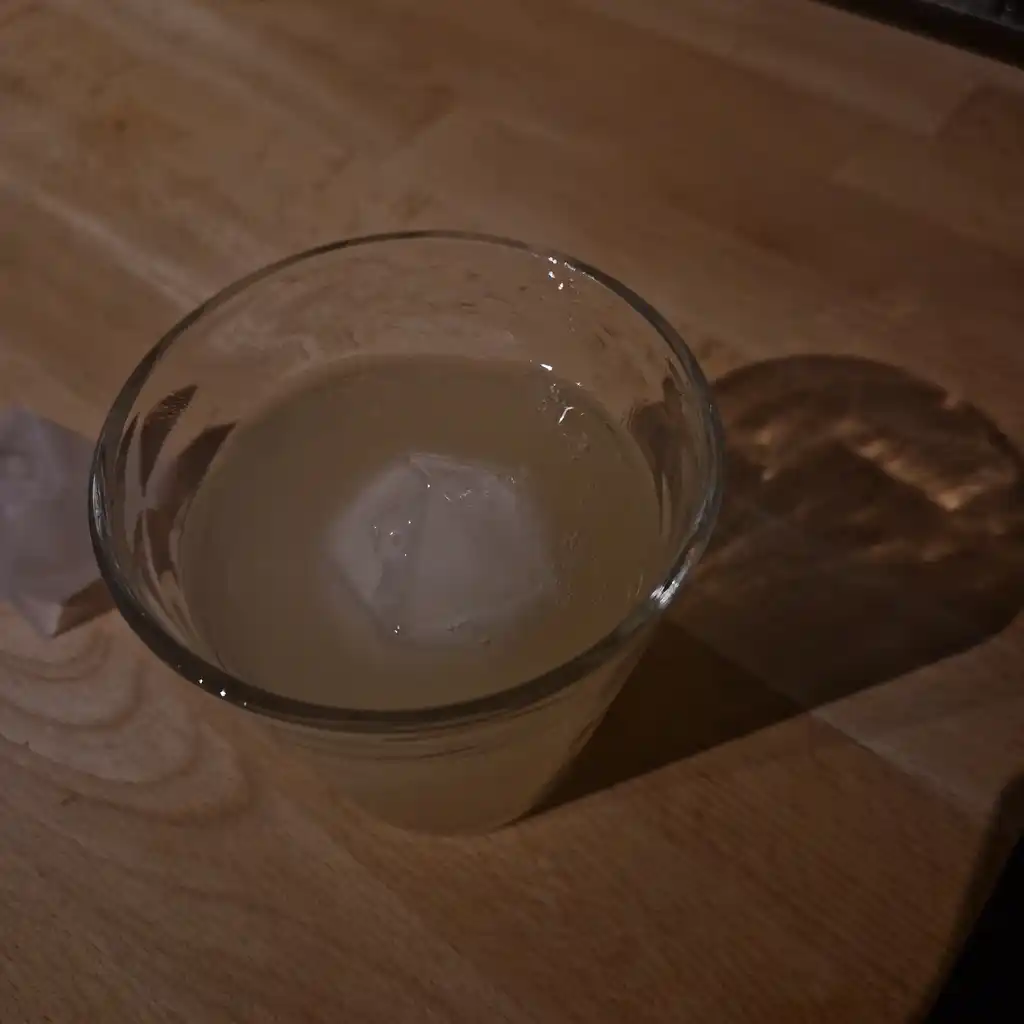

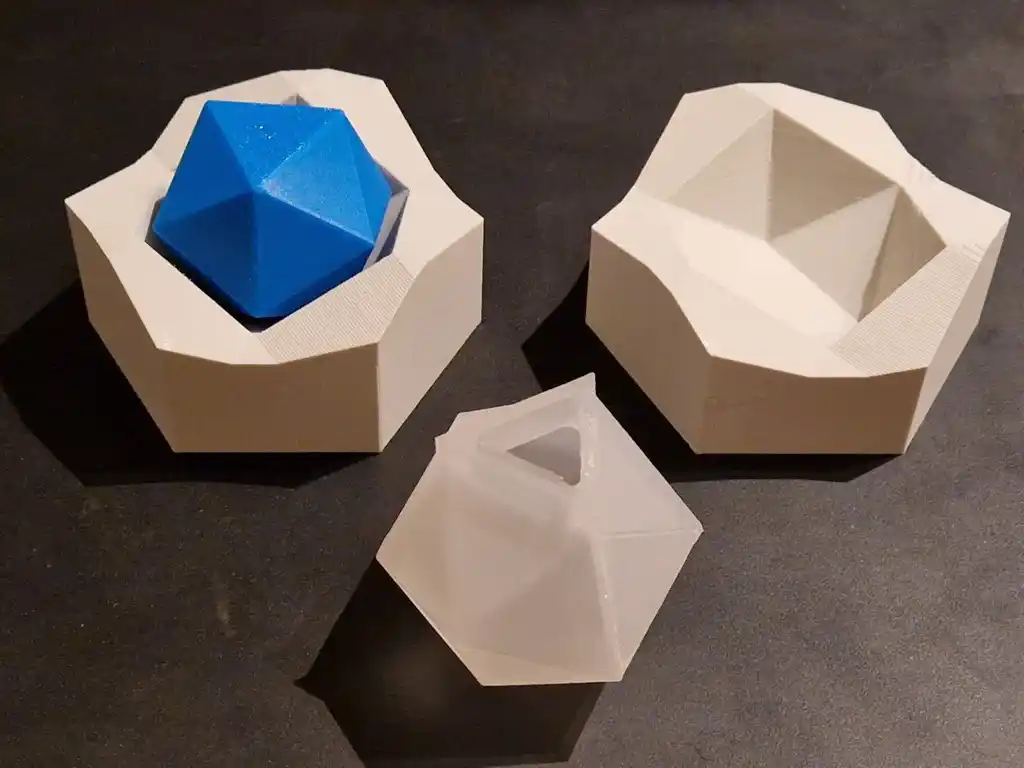

- A member - silicone D20 mould

- Dave - CNC machine calibration

- alifeee - CO2 monitoring

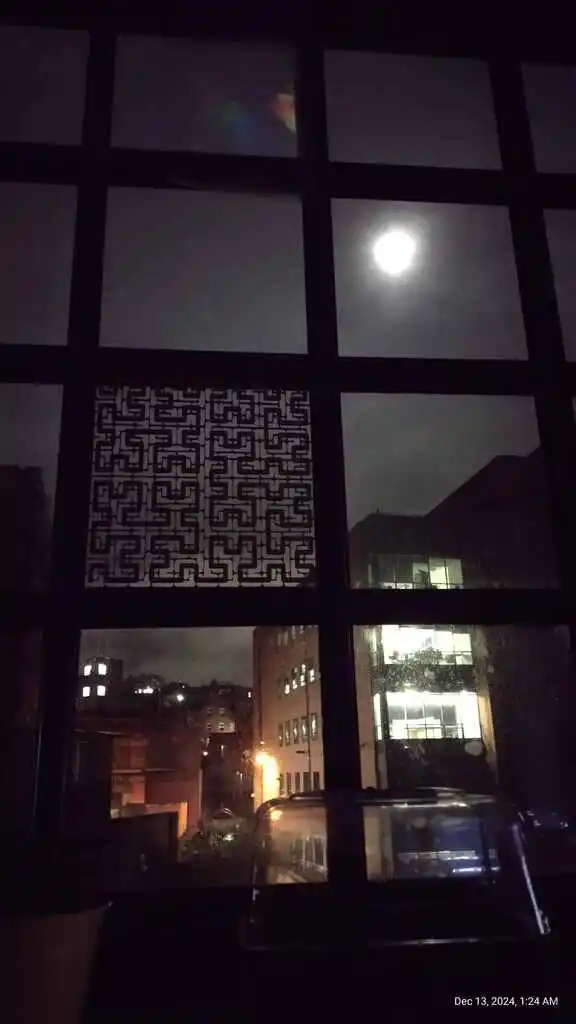

Nik - window decoration

Nik has laser-cut a hilbert curve that fits neatly as a window pane decoration. See more on Mastodon: https://mastodon.social/@nnenov/113380244822759727

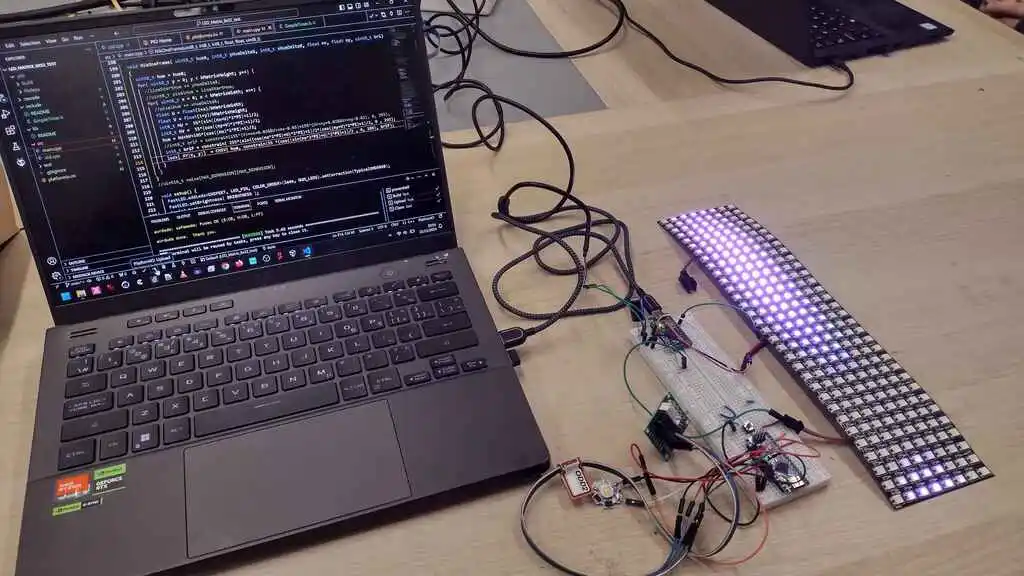

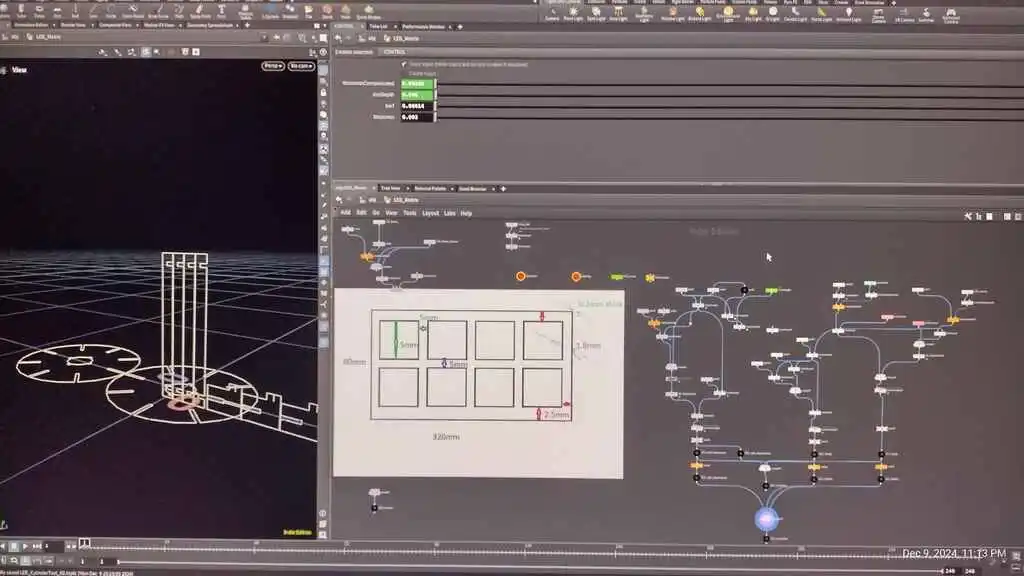

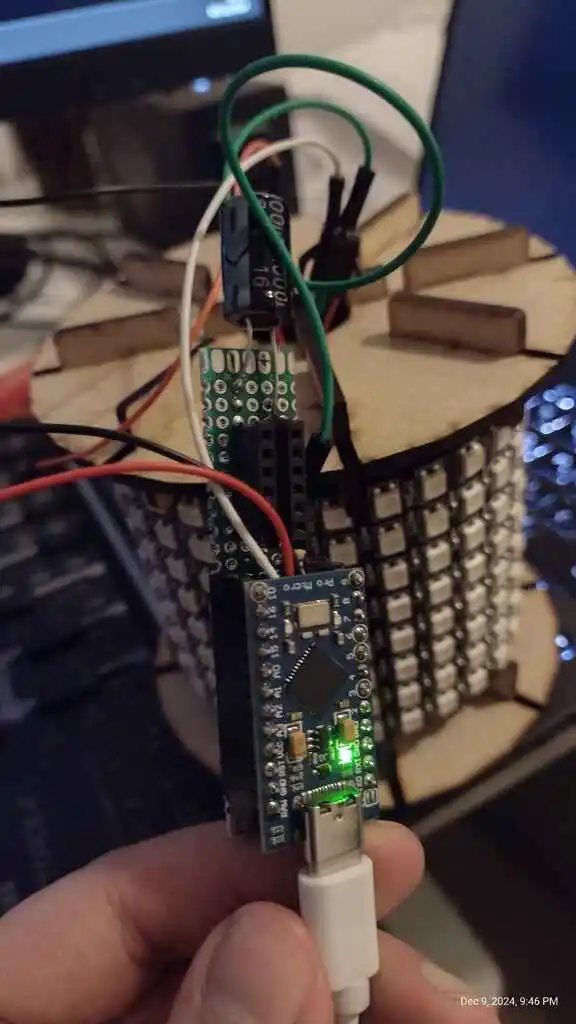

Nik - an LED device

Nik has also been learning PlatformIO. They used it to program an Arduino pro micro with an 8x32 matrix and the fastLED library.

It’s the first electronics thing I made which is not a sprawl of cables and just one single cable!

Again, see more on Mastodon: https://mastodon.social/@nnenov/113686610988811191

Alex - a trip to soft lab

Alex has been exploring weaving and knitting structures, coding in knots, textile motifs as symbols, bitfields, rhythm, movement, liveness, and the internet of patterns on a residency in Eindhoven.

See more on Mastodon: https://post.lurk.org/@yaxu/113485978426705451

Also see a paper from a few years ago about a mini version, also by Alex https://zenodo.org/records/3939176.

James - 3D printer in a backpack

James went to SMRFF 2024, a 3D printer festival in Manchester, for which they made a 3D printer which works in a backpack!

Adam - organised electronics

Adam has been organising their electronics with 3D printed inserts.

Tom - darning repairs

Tom bought a darning loom and used it to fix a hole in their jumper.

A member - silicone D20 mould

One member designed and made a silicone icecube mould. The mould geometry was designed in CAD and from it, a mould for the silicone was created. This 3-part mould was 3D printed using PLA & PVB. The printed mould-mould was assembled and a 2-part foodsafe silicone was cast into it.

Dave - CNC machine calibration

Dave from Desktop Machine Shop has been rebuilding a CNC machine…

I have just rebuilt the Milo v1.5 CNC machine with some upgrades:

- new more capable control board running RRF

- 55v power supply for motors to increase speed and torque

- new safety wiring so that SSRs are used to kill motor and spindle voltage without running high current through the e stop

The machined star was just me testing out that everything was working after the rebuild. But it will be a Christmas decoration when I’m done. I’ll drill a hole and pop some ribbon through it

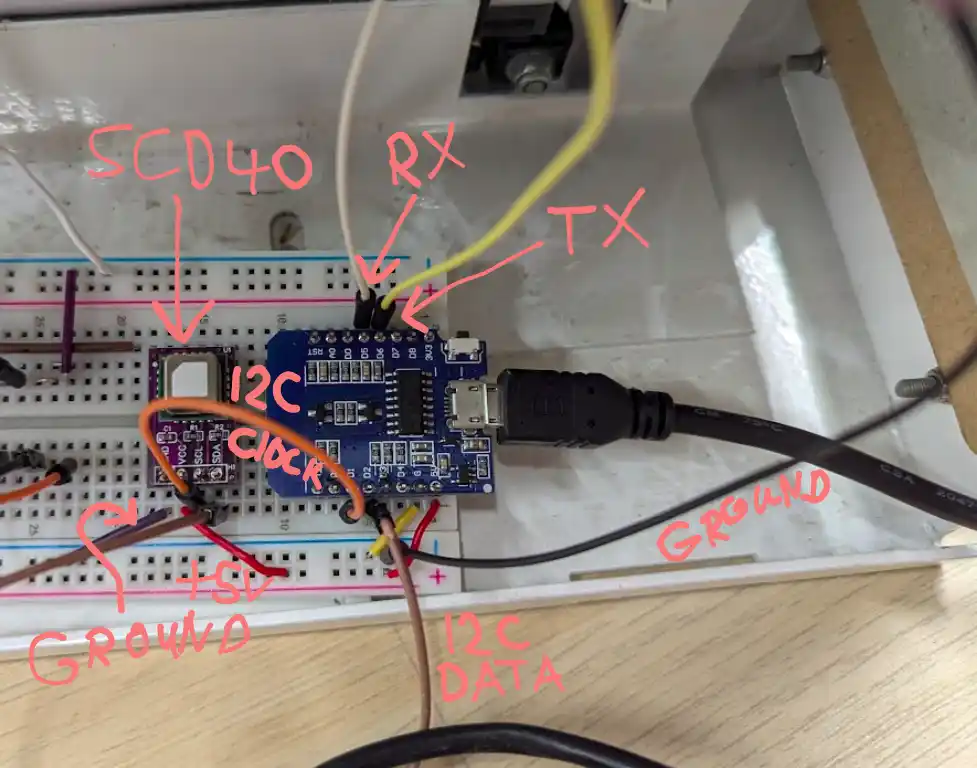

alifeee - CO2 monitoring

Finally, I set up a SCD40 CO2 monitor in the space, and attached it to the old train sign.

See a lot more information in the relevant GitHub repositories:

- CO2 train sign: https://github.com/sheffieldhackspace/co2-train-sign

- train sign: https://github.com/sheffieldhackspace/train-signs

That’s all

That’s all for this month! Remember, you can:

- come and visit the space! https://www.sheffieldhackspace.org.uk/calendar/

- add your own items to next month’s month update: https://github.com/sheffieldhackspace/month-updates

Until next time :)